Abstract

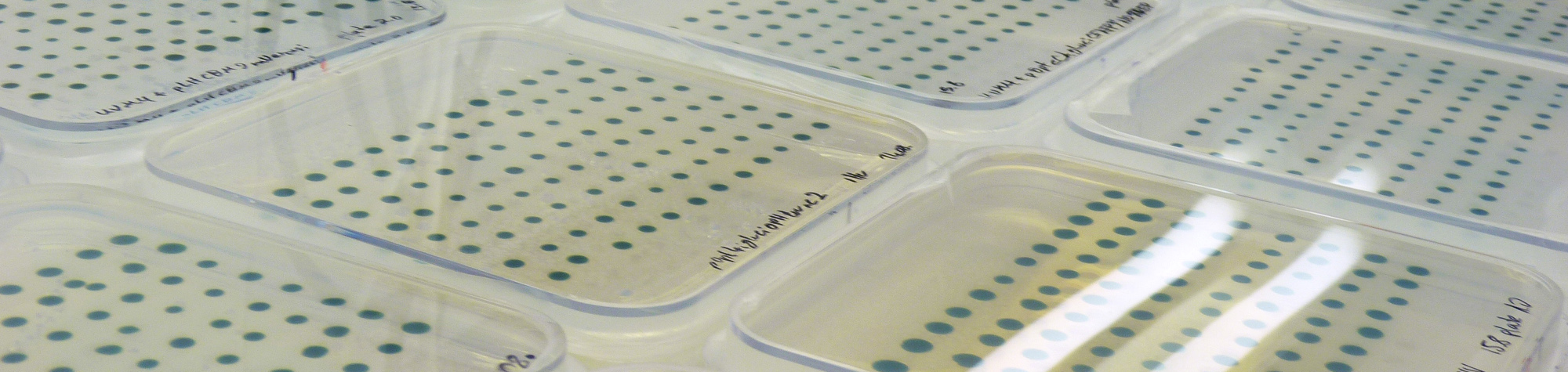

Membrane technology has numerous applications in potable water generation, wastewater (WW) reuse, desalination, and many others. However, the manufacture of membranes generates solvent-contaminated WW, especially via the non-solvent-induced phase separation method. Here, we tested the suitability of different microalgae to clean up membrane manufacturing WW and reuse it for subsequent membrane fabrication. Specifically, we determined the toxicity of six organic solvents to four different microalgae (Tetradesmus, Scenedesmus, Chlamydomonas, and Galdieria) and observed that all were able to tolerate solvent contaminant concentrations common to membrane manufacture with varying growth rates. Removal of triethyl phosphate varied greatly between strains, with >50% removal by cultures of Chlamydomonas and Galdieria, whereas PolarClean was almost entirely removed by Chlamydomonas, Tetradesmus and Scenedesmus. The four algae mentioned above, and two others, Monoraphidium and Chlorella were additionally grown in contaminated membrane manufacture WW, where the Tetradesmus, Scenedesmus and Chlorellaremoved PolarClean entirely, regardless of CO2 supplementation. The reuse of Scenedesmus-treated WW in a subsequent membrane fabrication did not affect the physicochemical properties of produced membranes, and the morphology of these membranes was comparable to control conditions. We observed that using photosynthetic microbes to clean membrane manufacture WW enables the generation of their valuable biomasses and the reuse of treated water for further membrane fabrication. Our results indicate that coupling biodegradable solvents and algal cultivation can enable circularity and reduce solvent emissions from membrane manufacturing processes.

Keywords

Wastewater treatment

organic solvents

Microalgae

PolarClean

circularity